Sigma Integrale

Sigma Integrale DK2+ Motion System

Sigma Integrale DK2+ Motion System

Couldn't load pickup availability

Share

The DK2+ system uses larger motors and actuators and is able to support more weight than the regular DK2. The larger motors offer a more powerful and torque-y feel than the regular DK2, and provide more attitude in the motion experience. The DK2+ is recommended for all sim center or similar commercial applications.

The DK2+ motion system is a professional motion system for serious sim-racing enthusiasts, drivers and researchers. The system shares the same design and construction as our industrial-grade motion systems used in our full motion vehicle simulators. Additionally, DK2+ is mechanically and electrically engineered around our unique motion algorithm to provide the most realistic and representative vehicle motion feedback.

DK2+ takes a modern approach to our signal processing and motion control to create the most responsive system on the market. Every elevation change, vehicle movement, surface change and gear shift, is captured and reproduced within 2” (50mm) of the available mechanical stroke.

If you do not have an available network port on your computer. Please feel free to use a USB to Network adapter such as this model available on Amazon.

For more information, please read our frequently asked questions here: FAQ

All motion systems are built to order and ship once rigorously tested. All systems include a 3-years warranty from date of purchase.

Contents

- mono-block, machined billet actuators with 2” (50 mm) travel

- powerful, responsive and compact American Teknic servo motors

- maximum weight capacity (chassis and driver):

- 3-actuator system = 600 lb (272 kg)

- 4-actuator system = 800 lb (363 kg)

- billet-machined floating feet with large rubber pads

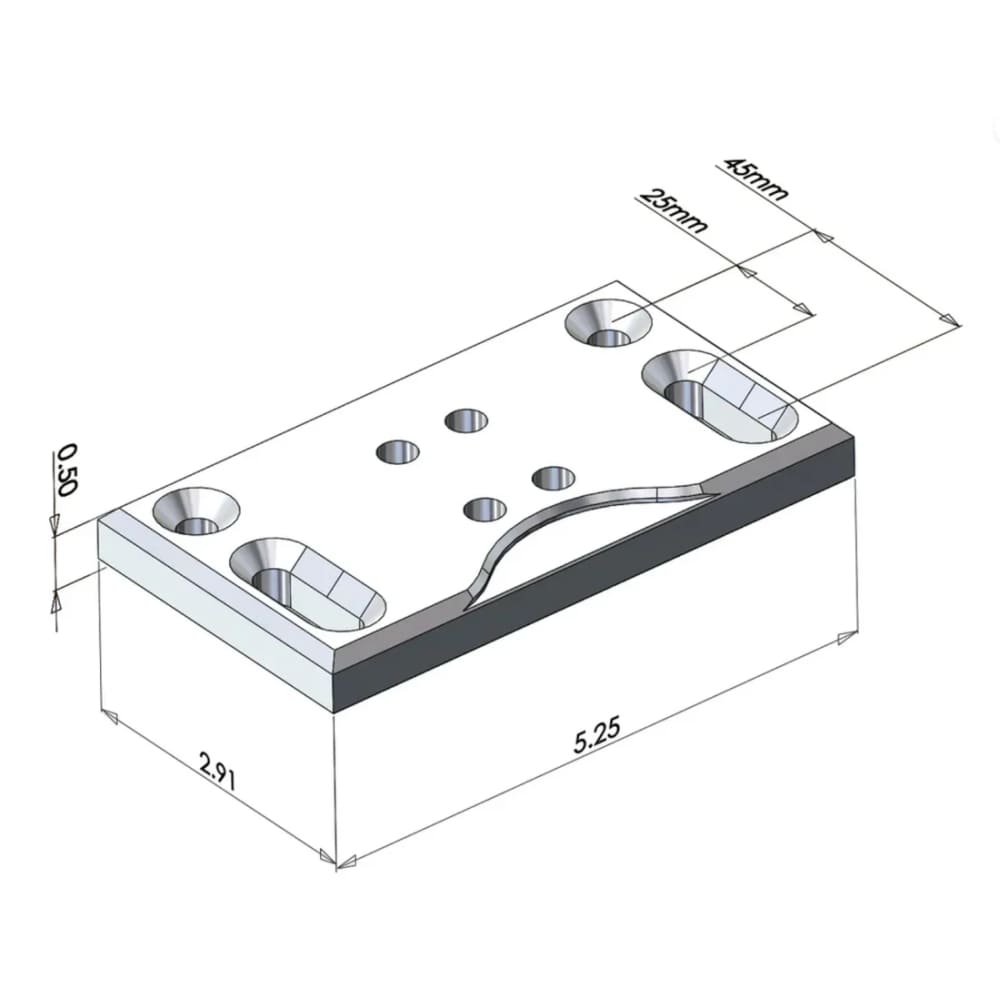

- aluminum t-slot mounting hardware compatible with 25 to 45 series profiles

- single controller box (115v/240V compatible) with power and network cables

- two sets of 1m and 2m data and power cables from the controller to actuators

- Sigma’s motion algorithms & simulation software

- automatic Over-the-Air controller firmware updates

Actuators

- 100% designed, manufactured, assembled and tested in California, USA

- Premium THK ball screw for smooth performance and durability

- Machined billet aluminum body to ensure concentricity and accuracy

- 2″ (50mm) in piston diameter for large side-loading capability

- T-slot aluminum extrusion friendly

- 16 lbs. (7.26kg) per actuator with the larger motor

- Environmentally friendly tumbled finish

Latency

-

PC side (Windows 10)

- Game physics engine @ 333 Hz: 3 ms

- Windows OS response: 1 ms average

- Sigma 10-layers algorithm: 1 ms

- Send target positions via Ethernet: 0.3 ms

-

Controller side (Real-time OS in ARM)

- Response to new position targets: < 1 microseconds

- Motion Algorithm for smooth motion: Average: 25 ms, Range: 0 to 50 ms

- Send motion data to 1st micro-controller at 1000 Hz: 1 ms

-

Controller side (2 low-latency micro-controllers)

- Send motion data from 1st micro-controller to 2nd: 0.1 ms

- Digital pulse generation: 0.002 ms

-

Electrical connection from 2nd micro-controller to ClearPath motor

- 3V to 5V conversion: 2 ms

-

ClearPath servo motor

- Digital pulse signal to actual motion: 1 ms

Technical

-

ClearPath Integrated Servo Motor CPM-SDSK-3432P-RLN

- Rated (RMS) Torque = 209 oz-in (1.5 N-m)

- Peak Torque = 698 oz-in (4.9 N-m)

- Max Speed = 2,380 rpm

- Total Weight Capacity (for optimal performance), including fully-loaded simulator with driver:

- 3-actuator system = 600 lb (272 kg)

- 4-actuator system = 800 lb (363 kg)

- Optically isolated, current-based I/O system (EMI free)

- Average system draw at 110V is about 0.330 KW (Peak 1600VA)

-

In-house manufactured actuators | 3D Model: Available Upon Request

- 2” (50mm) actuator travel

- speeds of 7.93"/s @ 2,380 rpm

- 5/8” diameter, USA ball screw and nut

- 2” (50mm) diameter piston

- Mono-block machined billet aluminum body

- All American made components

-

Motion Controller | 3D Model: Available Upon Request

- ClearPath IPC-5 Intelligent Power Supply

- Input voltage 95-125/190-250 VAC; 50-60Hz (NO INVERTERS REQUIRED!)

- Real-time and remote motion control via default browser or phone/tablet

- Signal processor with amplifier

- Embedded microcontrollers

- Shielded Molex connectors

- 15" wide, 9.25" deep and 3" tall

-

Sigma's Software and Algorithms

- Motion Integrity™ architecture to provide ultra-responsive, precise and accurate motion control

- Dynamic scaling algorithm to best represent all layers in the available actuator travel

- Organic and natural feeling Velocity Trap™ algorithm

- Smooth integration of the 10 motion layers

- Real-time remote control interface

- Custom Motion Profiles

-

Mounting hardware

- Machined billet mounting bracket

- T-slot aluminum extrusion (80/20) friendly

- Machined billet floating feet with mounting capability